The established safety standards for ICT equipment (60950-1) and AV equipment (60065) are to be phased out in favor of a single standard, 62368-1, in North America and the EU. The new standard introduces a different, hazard-based philosophy to product testing. What does it mean for product certification, and how can OEMs best manage the transition?

IEC 62368-1 2nd Edition, the hazard-based product-safety standard for ICT and AV equipment, is set to supersede the outgoing IEC 60950-1 for ICT equipment and IEC 60065 for AV equipment.

The move is more significant than a simple merger or name change, because 62368-1 adopts fundamentally different engineering principles and terminologies. In addition, some existing products that comply with 60950-1 or 60065 will need to be re-investigated to achieve certification.

To help product manufacturers manage the transition, the American and European bodies have harmonized the date from which the 60950-1 and 60065 standards will cease and 62368-1 will take over. Following a recent update to the EU’s Official Journal (OJ) of legislation, and subsequent announcement by UL in the USA, the new date is December 20, 2020.

Another important aspect is that, like the outgoing standards, 62368-1 applies not only to the end-user product but also to components and subsystems such as power supplies. Product manufacturers need to bear this in mind to be sure of procuring acceptable parts throughout the transition period between now and December 2020, and in the subsequent period when only 62368-1 will apply.

This paper aims to help manufacturers of affected products manage the transition and ensure continued compliance, by explaining the reasons for the new standard and its governing principles, the provisions built in to assist transition, and how best to ensure procured components like power supplies will satisfy its requirements.

December 20, 2020 represents an important date for companies marketing audio-visual products or computing/communications equipment in North America (i.e. USA and Canada) and the EU. The safety standards that historically have applied to these products, IEC 60065 and IEC 60950-1 respectively, will transition to IEC 62368-1.

In North America, December 20, 2020 is the UL Effective Date. UL will proceed with a soft transition, whereby new submissions for certification will be investigated against UL/CSA 62368-1, but existing products certified to the legacy standards will not be subjected to an Industry File Review (IFR).

In Europe, the transition will be more abrupt as the outgoing standards are withdrawn in favor of the new EN 62368-1 standard, and presumptions of conformity with directives that reference the old standards will also cease.

The intention has always been to harmonize the dates, so that manufacturers could plan and align their certification strategies for these two major markets of the world. Recently, a potential anomaly arose, as CENELEC extended the Date of Withdrawal (DoW) for the 60950-1 and 60065 standards in Europe to December 20, 2020, although the EU Official Journal was not updated at the same time. The problem lay with wording in the OJ (a legal document that takes precedence over the documentation for the standards) relating to the EU’s Low-Voltage Directive (LVD) allowing presumption of conformity for products that meet EN 60950-1 or EN 60065. In the OJ, the date of cessation of this presumption was June 20, 2019, which historically had been the same as the Date of Withdrawal of the outgoing standards.

In Europe, separating the DoW and the date of cessation of conformity introduced confusion about the status of EN 62368-1. From the American point of view, the separation prevented complete harmonization of the US Effective Date (from which UL 62368-1 will supersede UL 60950-1 and UL 60065 and they will be withdrawn) and the EU’s DoW/cessation of presumption of conformity.

On June 15, 2018, the date for cessation of presumption of conformity in the LVD was extended to December 20, 2020 in the EU’s Official Journal. This move had been expected, to clarify the status of EN 62368-1. Upon publication of the revised date, UL in America announced the extension of the US Effective Date, once again harmonizing the schedules for both markets.

As a single harmonized safety standard, IEC 62368-1 has been the work-in-progress of IEC Technical Committee TC108 since 2002. It is worth noting that TC108 is also responsible for IEC 60950-1 and IEC 60065, and has implemented changes in the latest editions of both to ease the transition to the new standard.

Following publication of the first edition of IEC 62368-1, in 2010, the North American Bi-National CSA/UL 62368-1 Ed. 1 was adopted in February 2012. At that time, the EU did not follow suit, but subsequently adopted the second edition as EN 62368-1 Ed. 2 in August 2014. CSA/UL 62368-1 Ed. 2 has been adopted in North America since December 2014. The Third Edition is expected to be published sometime in 2019, with the implementation date likely occurring in 2022.

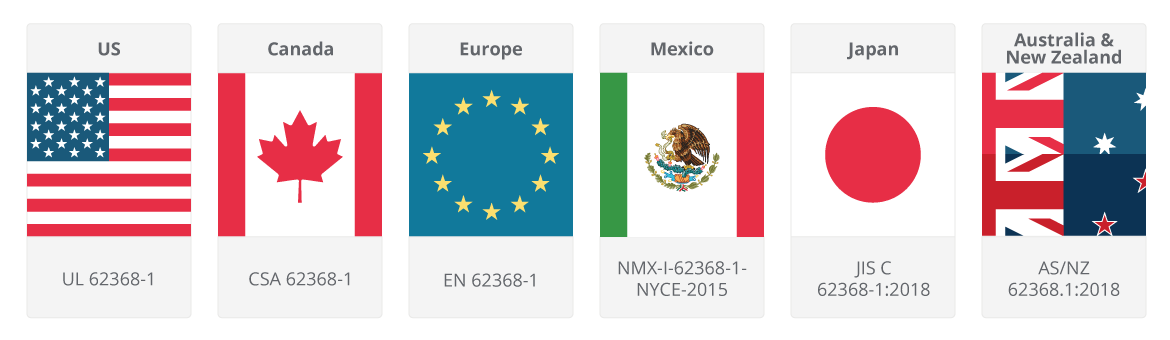

Although the North American and European standards bodies have already published their national equivalents (UL/CSA 62368-1 and EN 62368-1), committees in other regions are still evaluating adoption of 62368-1, including China, Korea, and South America. Mexico has implemented NMX-I-62368-1-NYCE-2015 on a voluntary basis. Japan published JIS C 62368-1:2018 in January 2018, based on IEC 62368-1:2014 Edition 2, and will take about a year to fully adopt it into law. The Australia/New Zealand standards authorities published AS/NZS 62368.1:2018, also based on IEC 62368-1:2014 Edition 2, in February 2018.

Currently, then, the 62368-1, 60950-1 and 60065 standards are active in both North America and Europe. Although the situation may sound complicated, the standards have been allowed to coexist to help the industry transition to the new standard as smoothly and cost-effectively as possible.

With the DoW for both 60950-1 and 60065 drawing close, manufacturers that have not yet engaged with the new standard are advised to do so now to ensure certifications to the new standard are secured in time.

As a unified replacement for 60950-1 (for ICT equipment) and 60065 (for AV equipment), 62368-1 represents more than just a merger of the two standards. The move is the latest evolution of Hazard Based Safety Engineering which has become the new approach as new types of affordable products have emerged for use in small and home offices, and for home entertainment.

With continued development of new technologies and new markets, the distinctions between AV and ICT equipment have become increasingly blurred – multimedia products provide just one example. A single harmonized standard aims to give a clearer framework to evaluate the safety of these products.

In addition, 62368-1 plans to give product designers more flexibility, in product design and evaluation and to keep pace with technology without requiring frequent (expensive and time-consuming) revisions. To this end it adopts the above mentioned modern Hazard Based Safety Engineering (HBSE) principles, which replace the traditional prescriptive approach of 60950-1 and 60065, although prescriptive options are also offered.

62368-1 applies to all equipment currently subject to 60950-1 and 60065 safety standards, and further products are to be brought within its scope.

Clause 1 describes the scope of the standard, while Annex A contains a list of product types covered. Currently, these include:

As with both 60065 and 60950-1, the examples provided in Annex A are not exhaustive, and equipment not listed is not necessarily excluded. Edition 3 of IEC 62368-1 is expected to include additional examples of equipment that has entered widespread use since the earlier standards were published. These could include smartphones, tablet computers, wearable computers, electronic kiosks and even 3D printers.

62368-1 applies not only at the product level but also – where relevant – to components and subsystems. This is the same situation that prevailed under 60950-1 and 60065, so companies that source third-party subsystems such as power supplies should inquire with the manufacturer to establish if the product is currently or has plans to be certified to 62368-1. This applies to units installed inside the equipment, such as chassis mount power supplies, as well as to external power supplies or adapters that are simply procured and shipped in the box with the equipment.

Second Edition of 62368-1 contains clauses designed to help companies manage their transition from the legacy standards. These effectively help companies decide how and when to certify their products to 62368-1, and to manage existing inventory of subsystems and components (like power supplies) that are already certified to 60950-1 and 60065.

An important – although, it must be noted, temporary – provision is the sub-clause 4.1.1, which enables companies to continue using their inventory of 60950-1 or 60065 parts in products certified to 62368-1. The clause states:

“Components & subassemblies that comply with IEC 60950-1 or IEC 60065 are acceptable as part of equipment covered by this standard without further evaluation other than to give consideration to the appropriate use of the component or subassembly in the end-product.”In the case of a Listed power supply, for example, due consideration can be as simple as ensuring the product is only used within its established electrical ratings.

Readers familiar with the requirements of 60950-1 and 60065 may have spotted the potential for some problems because the legacy standards classify energy sources and circuits differently. One example is that a 60950-1 certified switched-mode power supply typically has output circuits classified as safety extra-low voltage (SELV), whereas IEC 62368-1 refers to ES1 energy sources, which considers both voltage and current. As a result, SELV is no longer defined.

Although this is true, TC108 has taken a pragmatic approach to the issue, and has recognized that a SELV circuit is intended to be safe to touch by a user or operator, in the same way that an ES1 source is safe to touch by an ordinary person (see the section on “Hierarchy of 62368-1 Safeguards” for more information on user classifications). To aid transition to the new standard, the two are regarded as offering equivalent levels of safety. Hence, interconnection of 60950-1 SELV circuits and 62368-1 ES1 circuits is considered acceptable in practice without exhaustive analysis.

Note that sub-clause 4.1.1 is expected to be removed from future editions of 62368-1. TC108 has considered recommending that the provisions should be extended into Edition 3, which is currently being reviewed for publication. However, the European committee CENELEC intends to remove the legacy component provision 4.1.1 from Edition 2 of EN 62368-1, due to come into effect December 20, 2020, and has stated that it will not be featured in Edition 3, no matter the result of the TC108 discussion. UL, on the other hand, will maintain acceptance of 60950-1 or 60065 for legacy products after the 2020 date of withdrawal as long as significant changes involving safety of critical components are not made to the specific parts in question. Hence, companies must take these regional differences into consideration when preparing their transition plan to the 62368-1 standard.

To safeguard flexibility for designers at the same time as ensuring safety for end users, 62368-1 incorporates HBSE concepts. As a safety science discipline, HBSE has been formalized over the last 25 years to move product-safety legislation towards a performance-oriented philosophy which is more flexible (from standards-makers’ and designers’ perspectives) and effective (as regards to end-user safety) than prescriptive approaches. HBSE philosophy was ingrained in the ECMA-287 Safety of Electronic Equipment standard published in 2002, which was passed to the Hazard-Based Standard Development Team (HBSDT) of the IEC’s TC108 technical committee. TC108, among other IEC committees, has been committed to HBSE since the same period, and maintains several hazard sub-teams focused on electric shock, fire, mechanical, chemical, radiation and other hazards for various product types and safety standards.

Fundamentally, HBSE seeks to identify potential hazards as energy sources capable of causing pain or injury to users and identify suitable means of preventing such energy transfer.

The logic underlying HBSE can be summarized as follows:

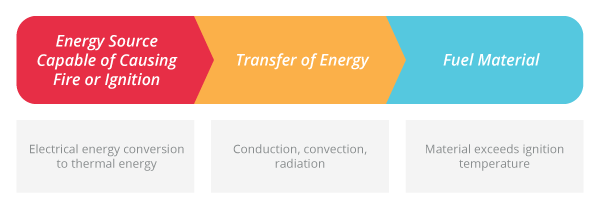

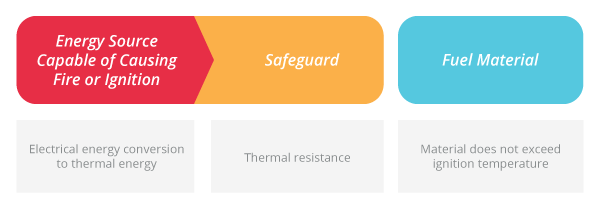

HBSE visualizes the hazards and safeguards in terms of three-block models that describe the links between energy source, energy-transfer mechanism (figure 1) or safeguard (figure 2), and the user.

Figure 1: HBSE visualizes how a user may be exposed to potentially harmful energy

Figure 1: HBSE visualizes how a user may be exposed to potentially harmful energy Figure 2: The HBSE three-block model allows a flexible approach to the design of safety features

Figure 2: The HBSE three-block model allows a flexible approach to the design of safety features Figure 3: Three-block model for analyzing potential causes of fire

Figure 3: Three-block model for analyzing potential causes of fire Figure 4: Three-block model for fire prevention

Figure 4: Three-block model for fire prevention

In addition to considering bodily injury, 62368-1 also applies the HBSE three-block model to analyze the potential for electrically caused fire resulting in damage to persons or property. Recognizing the need for a fuel to be present, if ignition is to occur, the three-block model is expressed in figures 3 and 4.

Moreover, 62368-1 references all energy sources applicable to ICT/AV electrical equipment. These encompass electrical energy, thermal energy such as hot accessible parts, chemical energy encompassing electrolytic reactions or poisons, kinetic energy such as moving parts, and radiated energy including optical or acoustic energy.

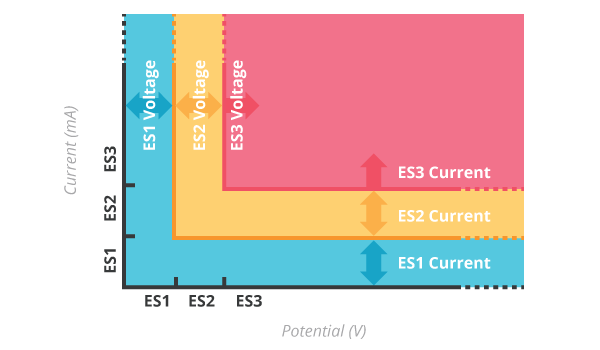

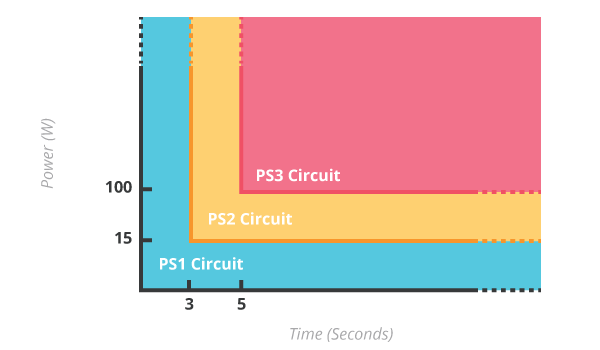

Energy sources are classified into one of three levels according to magnitude and duration, as an expression of their potential to cause harm. Figure 5 describes these classifications in relation to potential for bodily harm and fire risk.

| ENERGY SOURCE | EFFECT ON THE BODY | EFFECT ON COMBUSTIBLE MATERIALS |

|---|---|---|

| Class 1 | Not painful, but may be detectable | Ignition not likely |

| Class 2 | Painful, but not an injury | Ignition possible, but limited growth and spread of fire |

| Class 3 | Injury | Ignition likely, rapid growth and spread of fire |

No employed safeguard could be an option against class 1 energy sources, and the level of energy remains below specified class 1 limits under normal operating conditions, abnormal conditions, or in the presence of a single fault.

As far as class 2 energy sources are concerned, energy levels exceed class 1 limits but remain below class 2 limits during normal, abnormal or single-fault conditions. The energy present may be sufficient to cause pain but is not likely to cause injury. For fire analysis, the energy could be enough to cause ignition under some conditions. At least one safeguard is required to protect ordinary users from class 2 energy sources.

Class 3 energy sources are the most hazardous. The energy exceeds the class 2 maximum limit under normal, abnormal or single-fault conditions. Class 3 sources can cause injury, or ignition and spread of fire. The type of injury caused by a class 3 energy source may be fibrillation, cardiac/respiratory arrest, or skin and/or internal organ burn. A double or reinforced safeguard is required to protect an ordinary person from class 3 energy sources.

Figure 6: IEC 62368-1 energy levels and potential for electrically caused injury

Figure 6: IEC 62368-1 energy levels and potential for electrically caused injury Figure 7: Energy levels likely to cause electrical fire

Figure 7: Energy levels likely to cause electrical fire

Figures 6 and 7, relating to electrically caused injury and electrically caused fire, enable an intuitive understanding of classification of energy sources, and the safeguards required. The actual current and voltage limits applicable to ES1, ES2 and ES3 vary. For example, the voltage limit requirements are influenced by frequency. For voltages below 1 kHz, the ES1 limit is 30 Vrms, 42.4 Vp, and 60 Vdc. The ES2 limit is 50 Vrms, 70.7 Vp, and 120 Vdc. Equipment must comply with either the voltage limit or current limit specified in the applicable energy class but does not have to comply with both. The limits also vary according to normal or abnormal operation, or a single-fault condition. The limits are detailed in clause 5 of the standard. There are also sub-clauses, such as 5.2.2.5, which detail the limits for pulse waveforms, according to off-time. TC108 plans to remove 5.2.2.5 from Edition 3 of IEC 62368-1.

62368-1 makes provision for several kinds of safeguards, and defines a hierarchy ranging from basic safeguards at the lowest level, supplementary safeguards that become operational if the basic safeguard fails, double safeguards (such as double insulation), and reinforced safeguards, which are single safeguards that offer protection equivalent to that of a double safeguard.

Among the types of safeguards considered when developing a protection strategy, equipment safeguards are designed in and include protective earthing, electrical enclosures, fire enclosures, insulation or other protective features. There is also a provision for installation of safeguards, such as bonding to an external earth, as well as instructional safeguards such as safety marking. In addition, the standard references precautionary safeguards, which cover instances where users are instructed by skilled persons, and skills safeguards that permit reliance on the abilities of skilled persons to protect themselves against the hazards presented by class 2 and class 3 energy sources.

While the hazard-based approach that underpins 62368-1, and some of the terminology used, differs significantly from the approaches of 60950-1 and 60065, designers familiar with the older standards will recognize the distinctions between types of users. The term “ordinary person” in 62368-1 is equivalent to “user/operator,” and “skilled person” is equivalent to “service person.” 62368-1 also defines the category “instructed person,” which applies to those who have been instructed and trained – or are to be supervised – by a skilled person.

The hazard-based approach to safety analysis replaces the prescriptive approach adopted by each of the legacy standards. The basic intention of 62368-1 is to give designers greater flexibility to design safety measures in keeping with their products, while at the same time requiring rigorous analysis to ensure that all products are safe to use and cannot cause bodily injury or fire.

HBSE principles enable 62368-1 to support the introduction of new and innovative methods of construction and technology without first needing to be amended.

As a further advantage, the HBSE approach should help to minimize differences between published national/regional equivalents of the standard.

Some new test equipment is expected to be needed, to allow proper investigation of products. One key difference between the legacy standards and 62368-1 is the provision for a new type of probe for testing accessibility. A standard set of probes are used to assess the physical accessibility of energy sources within the product, and so determine whether one or more safeguards are needed. Annex 5 of 62368-1 describes the test methods used for determining accessibility and includes provisions for a new unjointed version of the standard articulated probe, for determining whether a part can be accessed by children.

For companies that have not embarked on the journey to understand the implications of 62368-1, and ensure continued marketability of current and future products, it is vital to begin preparing now. Studying the standard is essential, and supporting publications are also available to aid understanding.

To gain an overview of 62368-1, and its history, objectives and approaches, Clause 0 of the currently published standard presents an informative primer.

In addition, the document IEC/TR 62368-2, Ed. 2, “Audio/video, information and communication technology equipment – Part 2: Explanatory information related to IEC 62368-1” provides extra background and explanations of certain sub-clauses. This can be purchased online from the IEC store and elsewhere.

Change is coming. Like any new standard, the best response is to understand the reasons it has emerged, get inside, know all about it, and how best to work with it. By understanding what you must and must not do, you can make sure you are among the OEMs that are in a stronger position going forward, while leveraging the provisions of the new standard to deliver products that are in compliance.

Contact: Eason Wang

Phone: +86-755-13751010017

E-mail: info@iec-equipment.com

Add: 1F Junfeng Building, Gongle, Xixiang, Baoan District, Shenzhen, Guangdong, China